Some Nautical Terms I am trying to master ...

Abaft - near or at the stern

Abeam - to the side of the vessel, at right angle to the fore and aft line on a boat

Aboard - on a boat

About - on the other tack, to pass through the eye of the wind

Above Board – on deck

Abreast - alongside

Adrift - floating free without propulsion at the mercy of wind and current

Aft - i) the portion of the vessel behind the middle area of the vessel & ii) towards the stern (of the vessel).

Aground - stuck on the bottom in shallow water

Ahead – move forward

Alee - to leeward, away from the wind

Aloft - topsides

Amidships - in the centre

Anchorage - place suitable for anchoring in relation to the wind, seas and bottom

Anchor Ball – a black ball visible in all direction display in the forward part of a vessel at anchor

Anchor Light – a white light visible in all direction display in the forward part of a vessel at anchor

Apparent wind - wind felt on a vessel underway

Astern - going backwards

Athwart - across

Athwartships - running surface at the stern

Aweigh - anchor unhooked from the bottom

Ballast - weight in the keel or lowest part of the hull placed there to balance the boat

Bar - bank or shoal at the entrance of a harbour

Batten - wooden or plastic slat inserted in the leach of a sail

Beam - a boat's greatest width

Beam reach - point of sail where the boat is sailing at a right angle to the apparent wind

Beamy - a wide boat

Bearing i) direction of an object expressed either as a true bearing as shown on the chart, or as a bearing relative to the heading of the boat; ii) water lubricated bearing that support drive shaft in front of propeller.

Beating - going toward the direction of the wind, by alternate tacks

Bend – i) make fast ii) a knot by which one rope is made fast to another

Bilge - the lowest part inside a boat's hull.

Bitter End - last part of a rope or chain the inboard end of the anchor rope

Block - nautical pulley

Block and line – an arrangement of pulleys and line which increases hoisting power for heavy work, such as pulling in the sail in a strong breeze

Boom - spar that holds the foot of the mainsail

Boomvang - tackle or hydraulic ram that restrains the boom from lifting

Boot stripe - different color strip of paint at the waterline

Boot top - painted band on the boat's topsides just at the waterline

Bottom - that part of a boat's hull under water (the under-body)

Bow - the most forward part of a boat

Bow Line - docking line leading from the bow

Bow Spring Line - bow pivot line used in docking (and undocking), or to prevent the boat from moving forward or astern while made fast to a pier.

Broach – a sudden, unplanned, and uncontrolled turning of a vessel so that the hull is broadside to the seas or to the wind

Bulkhead - wall separating a boat's cabins and providing structural integrity

Bulwark – a solid rail along ship-side above deck to prevent men and gear from going overboard

Buoyancy - the upward force that keeps a boat floating

Canvas - sails or area of the sails

Cast Off – To let go.

Chain – i) The rope or chain made fast to the anchor ii) 120 fathoms in length.

Chainplates - straps on the hull to which stays and shrouds are secured

Chock - an object to which line are secured on-board

Cleat – a fitting, usually with two horn-shaped ends, to fairlead for the anchor rode and docking lines

Clew - the after lower corner of a sail

Combing - a low wall around a cockpit

Cockpit - a recessed area in the deck containing the tiller or wheel

Companionway - an opening with steps leading down from the deck to the cabin

Deck - the top of a hull

Displacement – a boat's weight or the weight of the water displaced by a boat

Dodger – a piece of canvas protecting the cockpit sides

Draft - the distance between the waterline and the lowest part of the keel

Drift – a vessel’s leeway.

Drive Saver – a barely flexible coupling that softens the shock of immediate gear engagement - they break the electrical connection between the engine/transmission and the shaft and prop.

Ebb Tide – is a receding tide, a period or state of decline.

Even Keel - a boat is floating on its designed waterline, it is said to be floating on an even keel.

Fairlead - a fitting through which a line passes so chafe is avoided

Fairway - the middle of a channel or between piers in a marina

Fathom – 6 feet

Fender - a bumper hung between a boat and a float or a pier

Foot - the bottom edge of a sail

Forepeak - storage compartment in the bow

Foresail - a jib

Forestay - a stay running from the foredeck to the upper part of the mast

Freeboard - distance from the deck to the water

Furl – to roll up a sail snugly

Furling sail - a sail that rolls around a boom or head stay

Galley - a boat's kitchen

Genoa - a large jib, which overlaps at least part of the headsail

Gooseneck - a fitting securing the forward end of the boom to the mast

Ground tackle - anchor plus anchor rode.

Hatch - opening in a deck covered by a hatch cover

Headway - traveling towards the destination

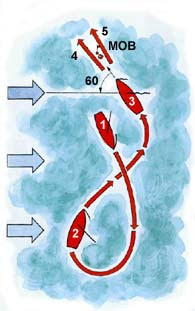

Hove To - a manoeuvre in which sails are set to minimize the boats headway

House - the roof of the cabin extending above deck

Hull - the boat's shell, exclusive of deck, cabin and rig

Jib - a sail carried on the head stay or forestay

Jibing (Gybing) - changing the boat's direction when the wind is from the back

Kedge Off - use an anchor to pull a grounded boat to deep water

Keel - an appendage under the hull that counteracts leeway and heeling forces

Knot – i) a measure of speed equal to one nautical mile (6,076 feet) per hour; ii) A fastening made by interweaving rope to form a stopper, to enclose or bind an object:

Lanyard – a short line used for making anything fast or used as a handle.

Latitude - distance north or south of the equator measured and expressed in degrees.

Launch - putting a boat into the water

Layout - arrangement of gear on deck or furniture in the cabin

Lee - side sheltered from the wind, if a vessel has the wind on her starboard side, that will be the weather, and the larboard will be the lee side, under the lee of anything, is when you have that between you and the wind.

Leech - the after edge of a sail

Leeward - the lee side, in a direction opposite to that from which the wind blows, which is called windward, the opposite of lee is weather, and of leeward is windward.

Leeway - sideways movement of the boat caused by either wind or current.

Length - Overall (LOA) - distance between tip of bow and end of stern.

Length - Waterline (LWL) - most forward and aft points touching the water when the boat is at rest

Lifeline - a coated wire, supported by stanchions, that encircles the deck

Line - any length of rope that has a specified use

Longitude - distance in degrees east or west of the meridian at Greenwich.

Luff - the forward edge of a sail

Mainmast - the tallest of two masts on a boat

Mainsail (Pron. mains'l) - the sail hoisted on the after side of the mainmast

Mast - the wooden or aluminium pole supported by standing rigging.

Masthead - the top of the mast

Masthead (Steaming) Light - located about two-thirds of the way up on the mast

Maststep - the support for the bottom of the mast

Nautical Mile - Nm = 1,853 metres = 2,000 yards = 6,080 feet Contrary to some earlier replies, a nautical mile is (or was) the length of a minute of latitude at the latitude in question, not at the equator.

Navigation lights - that are illuminated at night

Neap Tides – Low tides, coming at the middle of the moon`s second and fourth quarters.

Outhaul - a sail control that secures the clew of boomed sail

Painter - a bow line on a dinghy

Pendant (Pron. pennant)

Personal Floating Device PFD - term for a life jacket or other approved item to support flotation

Point - to sail close into the wind

Port (1) left side of boat looking forward; (2) a commercial harbour

Porthole - a small round window

Preventer - a line that prevents a boom from jibing accidentally

Pulpit - a stainless-steel guardrail around the bow

Pushpit - a stainless-steel guardrail around the stern

Quarter – i) part of a vessel`s side between the after part of the main chains and the stern, ii) the wind is said to be quartering, when it blows in a line between that of the keel and the beam.

Racer-Cruiser - a boat comfortable enough for cruising and fast enough for racing

Race - strong, rippling tide.

Rig - the spars, standing rigging and sails

Rode - the anchor line (chain and/or rope)

Roller furler - a device for rolling a sail for storage while still in the rigging

Rudder - an underwater board that is adjusted by helm to steer the boat

Running Lights – Navigation lights required to be shown on boats underway between sundown and sunup.

Safety harness - worn on the upper body and attached to the deck with a tether

Sail Controls - lines, tackles, and other gear to hold a sail in position and adjust its shape

Scope - ratio of the length of an anchor line, from a vessels bow to the anchor, to the depth of the water.

Scupper - deck or cockpit drain

Sea Anchor – a device used to reduce a boats drift before the wind.

Seacock - valve opening and closing a pipe through hull valve, a shut off on a plumbing or drain pipe between the vessel`s interior and the sea boat.

Seaworthy - able to survive heavy weather

Shackle - U shaped connector with a pin or bolt across the open end.

Sheave - wheel in a block upon which the rope works.

Sheet - primary sail control line which pulls the sail in and out

Short line - a short length of wire or line used as an extender

Shroud - side stay or a line or wire running from the top of the mast to the spreaders, then attaching to the side of the vessel.

Skeg - small fixed fin attached to the underbody near the stern

Sloop - a single-masted boat that flies one jib at a time

Sole - a cabin or cockpit floor

Spar - any mast, boom or spinnaker pole

Speed - the theoretical maximum speed of a displacement hull through the water.

Spinnaker - a light ballooning sail

Springs - highest and lowest course of tides, occurring every new and full moon.

Sprayhood - a fold up or fixed spray shield at the forward end of the cockpit

Spreader - an athwart ships strut holding shrouds out from the mast and providing lateral support

Stanchions - metal posts supporting lifelines

Starboard - the right side, facing forward

Starboard Tack - vessel is on the starboard tack, or has her starboard tacks on board, when she has the wind on her starboard side.

Stay - a wire supporting the mast

Stem - stiff behind, towards the stern

Stern - the aftermost part of a boat

Stern Gland - a coupling between an engine's gearbox and driveshaft

Stuffing Box - the place where the drive shaft exits the hull

Tacking - changing a boat's direction when sailing into the wind

Toe Rail – a small rail around the deck of a boat, the toe rail may have holes in it to attach lines or blocks.

Topping Lift - a line or wire that holds up the boom or spinnaker pole

Transom – makes the stern

Traveller - an athwart-ships’ running tracks on which slides a car connected to the main-sheet blocks.

Trim - Fore and aft balance of a boat.

True Wind – the actual direction from which the wind is blowing

Turnbuckle - a threaded fitting used to adjust a stay's length

Variation - angular difference between the magnetic meridian and the geographic meridian at a particular location.

Weather or Lee Beam - direction to windward or leeward, at right angles with the keel.

Winch - a geared drum turned by a handle used to pull halyards, sheets and other lines under strain

Windlass - special type of winch used for pulling the anchor rode

Yacht - a pleasure boat

Yawl - swing off course, as when due to the impact of a following or quartering sea.